The history of Saint Jean Industries

From French aluminum foundry to international supplier...

It is in 1962 that the company of the Garavoglia Brothers was born, with a capital of 130 000 francs and 6 people. It is specialized in the aluminium foundry of small parts.

It is during the crisis of the 70s that Thomas Di Serio enters the company. He reorganized the company's activity before taking over the management and naming it "Fonderie de Saint Jean".

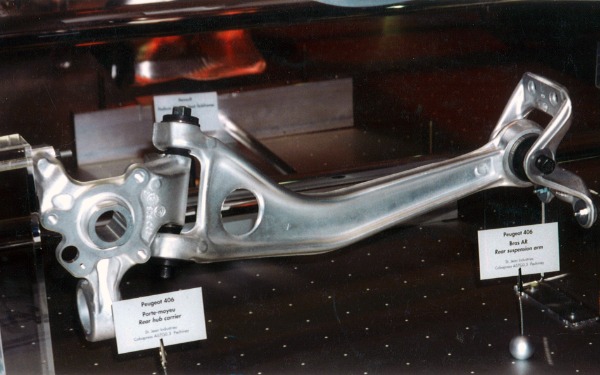

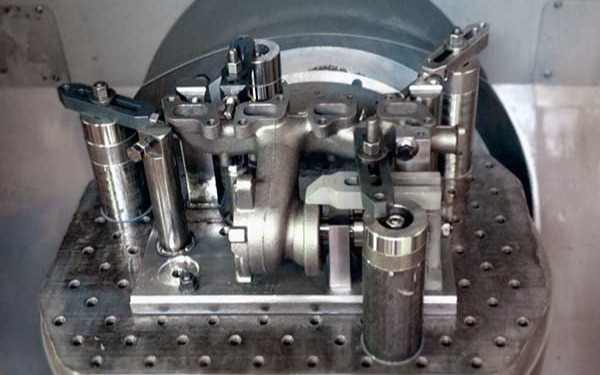

Thomas Di Serio invented the COBAPRESS™ (COuler, BAsculer, PRESSer) manufacturing process in 1982. The goal was to improve the mechanical characteristics of bicycle cranks.

A license for COBAPRESS™ is granted to a French car manufacturer. Following favorable tests on ground connection parts, the technology is approved.

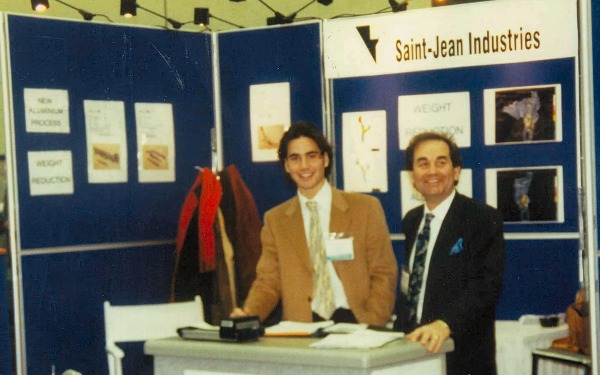

For its first participation in the SAE show in Detroit, SJI is taken very seriously by the American manufacturers. The first projects were initiated. Exports were developed, and a license was granted to the American leader in the manufacture of car rims, SUPERIOR INDUSTRIES. So much so that a dedicated site was built in Heber Springs, Arkansas.

The company is growing rapidly. The headquarters site expands and integrates more and more technologies, including the first fully robotized production line. Emile Di Serio takes over from his father and strengthens the international dimension of the group.

Saint Jean Industries sets up in Slavonski Brod in Croatia to increase its capacity in Europe. This new production site will benefit from the group's expertise in aluminum casting and machining. Four years later, in the same spirit, the German company AGR GmBH located in Leipzig is bought.

A license for the COBAPRESS™ patent is assigned to the equipment manufacturer MYUNGHWA INDUSTRIES. This South Korean group is specialized in the manufacture of chassis and engine components. From this agreement, a production site dedicated to the manufacture of COBAPRESS™ ground connection parts will be born.

This will be followed in 2005 and 2007 by the opening of sales offices in China and Japan.

The American SUPERIOR INDUSTRIES reorganizes its activities. It has decided to focus on its historical market of aluminum wheel manufacturing. This forces it to separate from its production site for aluminum and COBAPRESS™ cast chassis parts. The SJI group seizes the opportunity and buys the site which becomes Saint Jean Industries Inc.

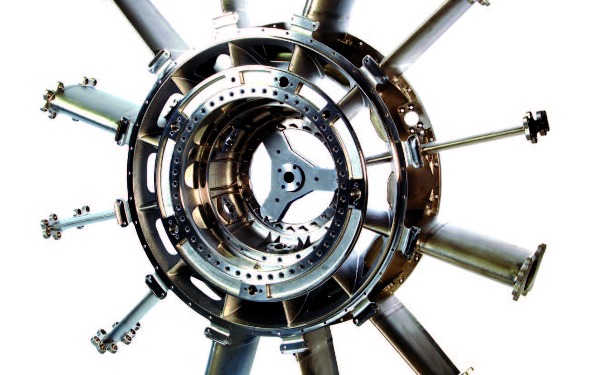

The Di Serio family acquires the company BERINGER. This French company specializes in the manufacture of high performance braking systems for cars and motorcycles. A license agreement is signed for the exploitation of BERINGER technologies and the supply of braking equipment as original equipment.

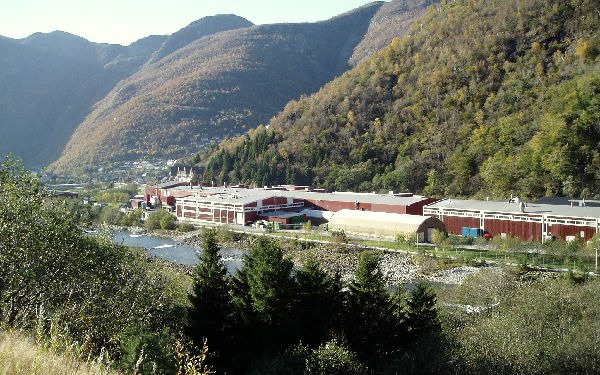

Saint Jean Industries takes over the technologies of the Norwegian company FUNDO specialized in the manufacture of aluminum wheels. FUNDO becomes Saint Jean Wheels. This takeover will allow the development of the COBAWHEELS™ technology allowing the lightening of aluminum rims.

51% of the shares of FOURNIER SA are bought with the help of the FMEA rank 2. The objective is to strengthen the group's engine division with its expertise in hard metal machining and its prototyping capacity. FOURNIER SA becomes Saint Jean Industries Lorraine.

Acquisition of a subsidiary of the RUAG aerospace group. The Swiss company is recognized for its expertise in the machining of complex structural parts in titanium and inconel. The new entity becomes Saint Jean Aero, the reference competence center in its market.

Rescue of the FDPA (Fonderie Du Poitou Aluminium) allowing the preservation of most of the jobs of the site. FDPA produces aluminum cylinder heads and engine parts. For SJI, this choice of takeover is part of its strategy of product diversification through external growth.

The motor division continues to strengthen with the inauguration of the extension of the site in Croatia. This extension will be dedicated to the machining, assembly and testing of aluminum compressor housings.

Saint Jean Industries reveals about ten product/process innovations allowing, among other things, the lightening of the vehicles.

This same year, Saint Jean Industries wins one of its biggest contract with the group FCA (Fiat Chrysler Automobile). This contract concerns the supply of parts manufactured in traditional aluminium foundry and COBAPRESS.

The American site in Heber Springs is investing heavily in automated lines to meet growing customer demand.

With a strong desire to diversify its business, Saint Jean Industries sets up in Valladolid, Spain. Specializing in the manufacture of parts for electric vehicle motors and batteries, core components for trucks and agricultural machinery, and for the boiler industry, SJI Valladolid is an expert in EPGS aluminum casting, machining and assembly.

The company has also set up in Stuttgart, Germany. This site is renowned for its expertise in machining, bending and assembling complex sub-assemblies for lightweight aluminum structures and battery packs for electric vehicles.

Saint Jean Industries decides to invest in the fast-growing Asian market and sets up in the Changshu industrial zone, located near Shanghai in China.

From design to assembly, our 25,000m2 Chinese site offers chassis and suspension parts using gravity and low-pressure molding processes, as well as COBAPRESS technology.

For several years now, Saint Jean Industries has been very involved in decarbonization and in wanting to protect our planet as much as possible from CO2 emissions in order to slow down global warming.

We have therefore embarked on a project to install solar panels on the roofs of our various sites, as well as building "solar carpots" with the aim of becoming "carbon neutral" by 2039.

Expansion of the Changshu site will begin in June 2024. This second construction phase covers a total surface area of 33,000 m2 and will include two new buildings with a total surface area of 25,000 m2.

This second construction phase will also include a new subframe production line to enable Saint Jean Industries to meet new automotive demands on the Asian market, bearing in mind that we already have a site in Germany specializing in BIW parts.