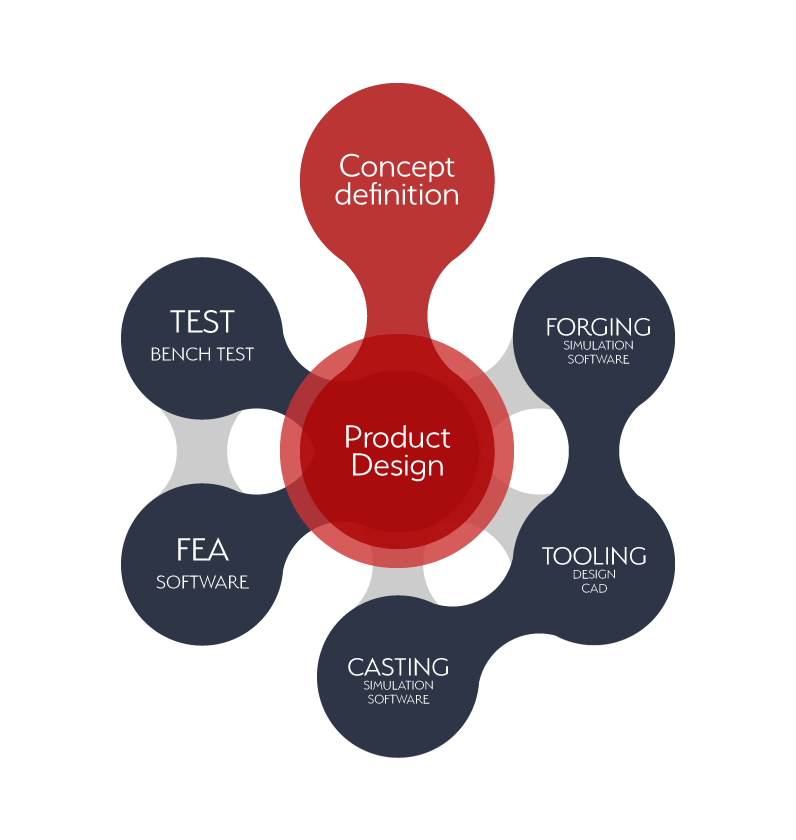

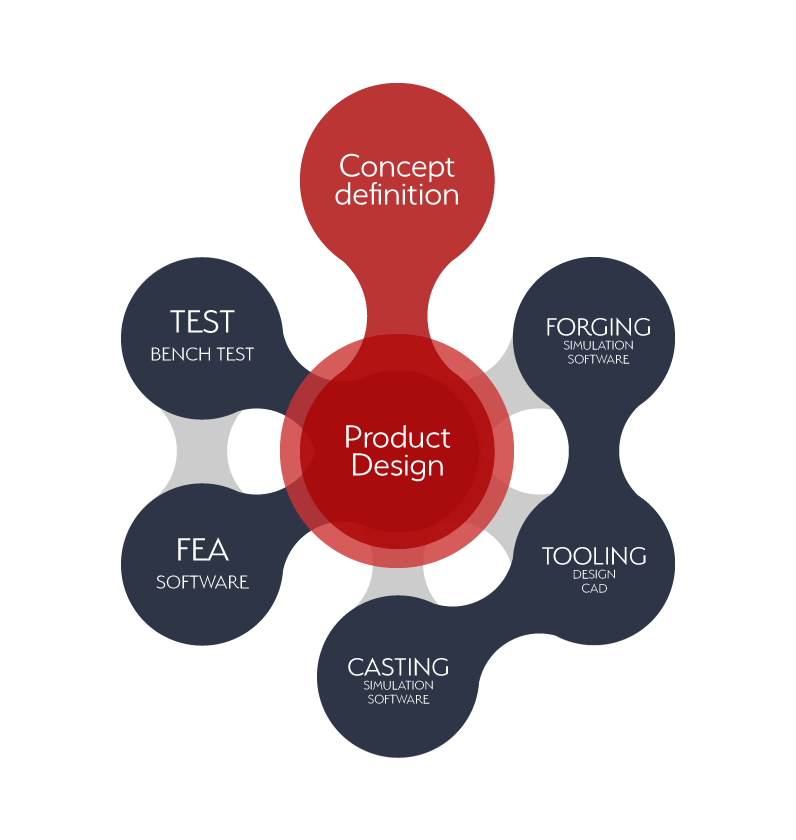

From the very early stages of design of parts and sub-assemblies, to mass production, our engineering can support you in all phases of your project:

Saint Jean Industries provides complete engineering support, from part design to mass production. All studies and developments are done in-house in conjunction with our various divisions.

Our design office brings you its expertise in the drafting of specifications, as well as the development of parts to meet them.

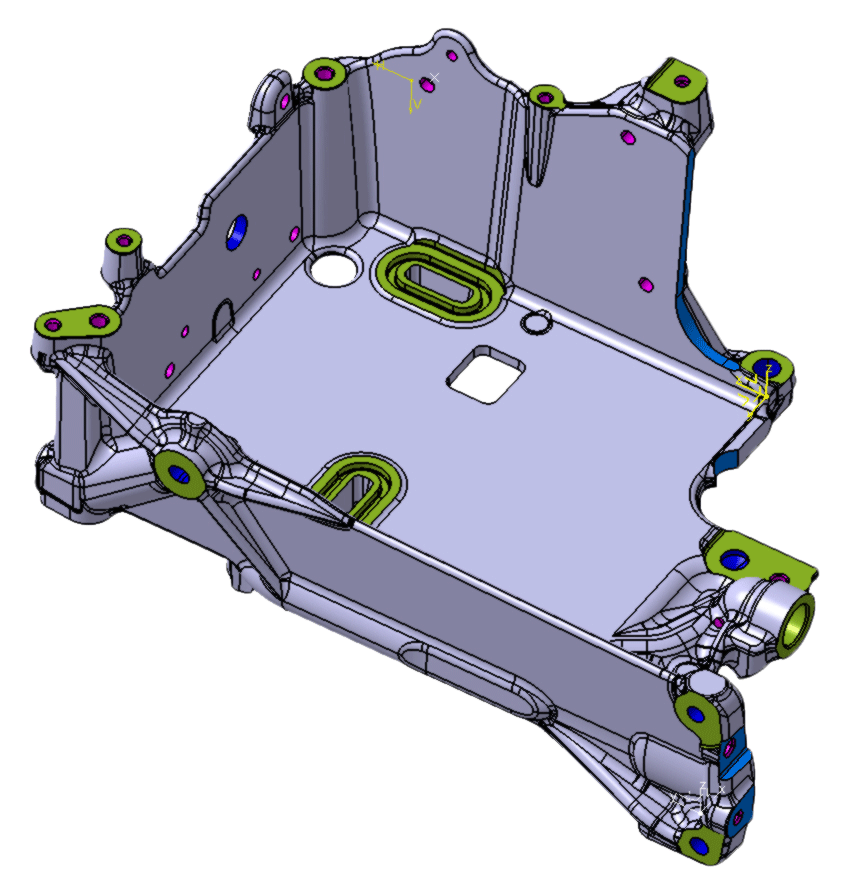

The design of parts and sub-assemblies can be carried out from predefined constrained environments. It is also possible to optimize a pre-design to achieve weight or space saving objectives for example.

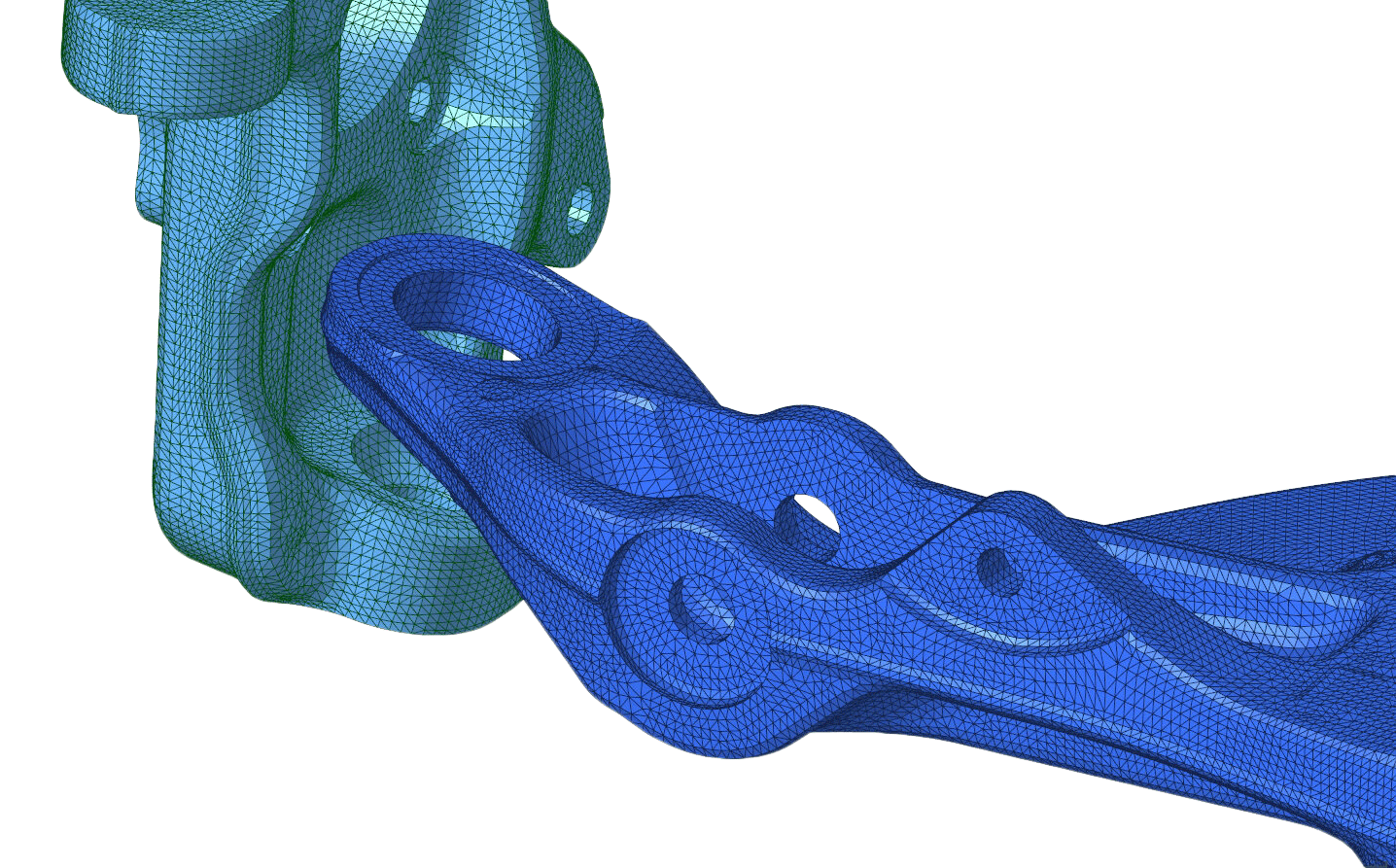

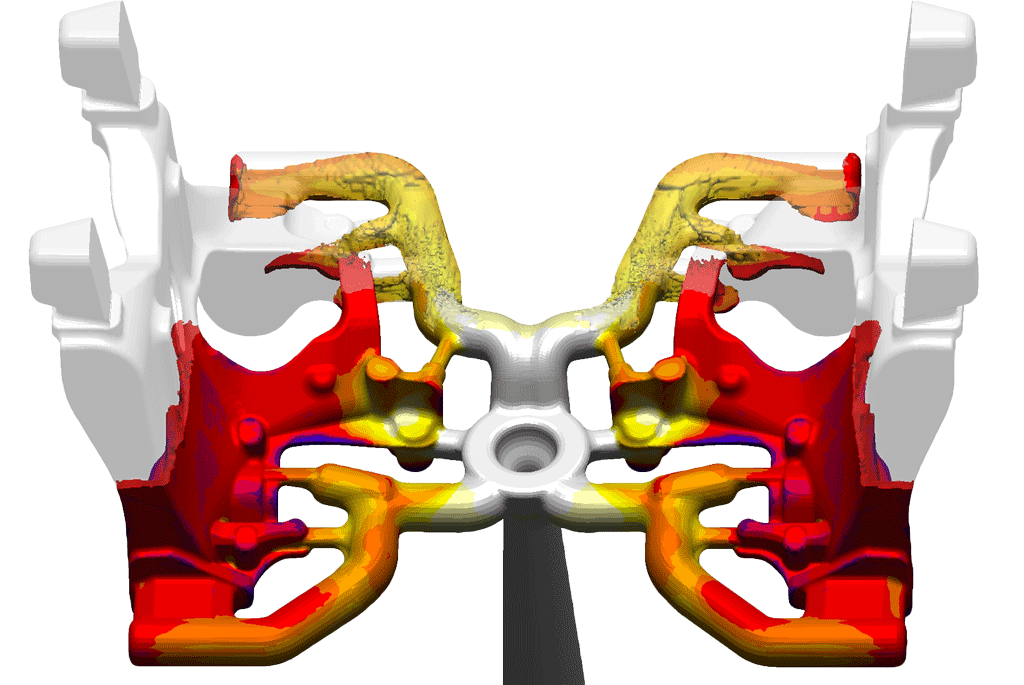

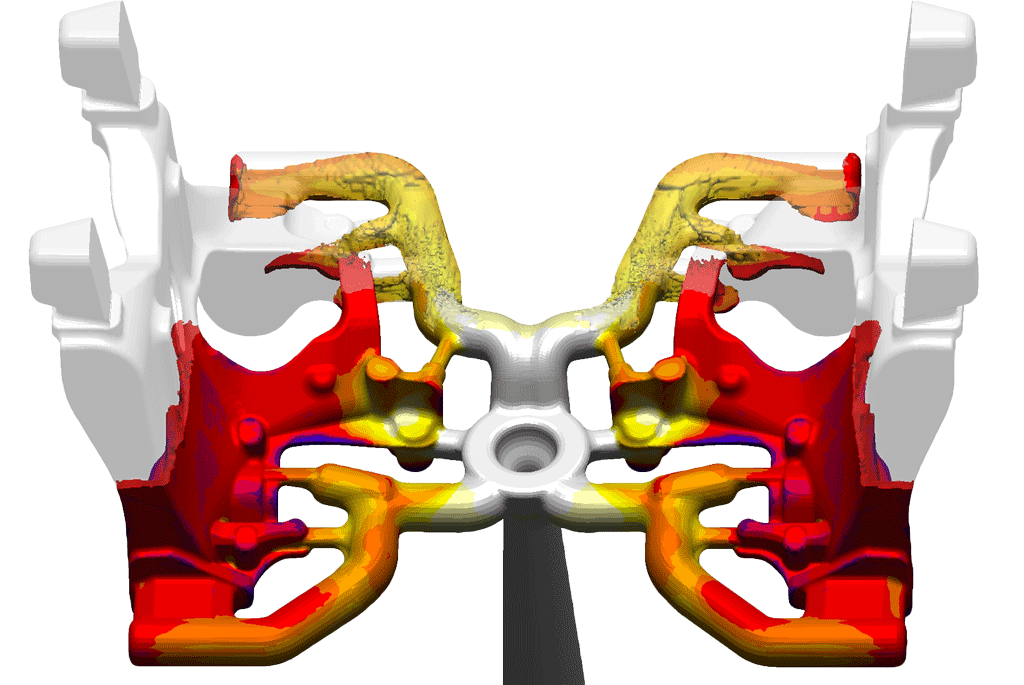

Our models are tested in finite element calculations, and thus determine if the chosen design meets the specifications. This phase allows us to optimize the design.

In the design loop, different iterations also integrate the foundry and/or forging simulation. This step is essential to ensure the feasibility of the designed parts.

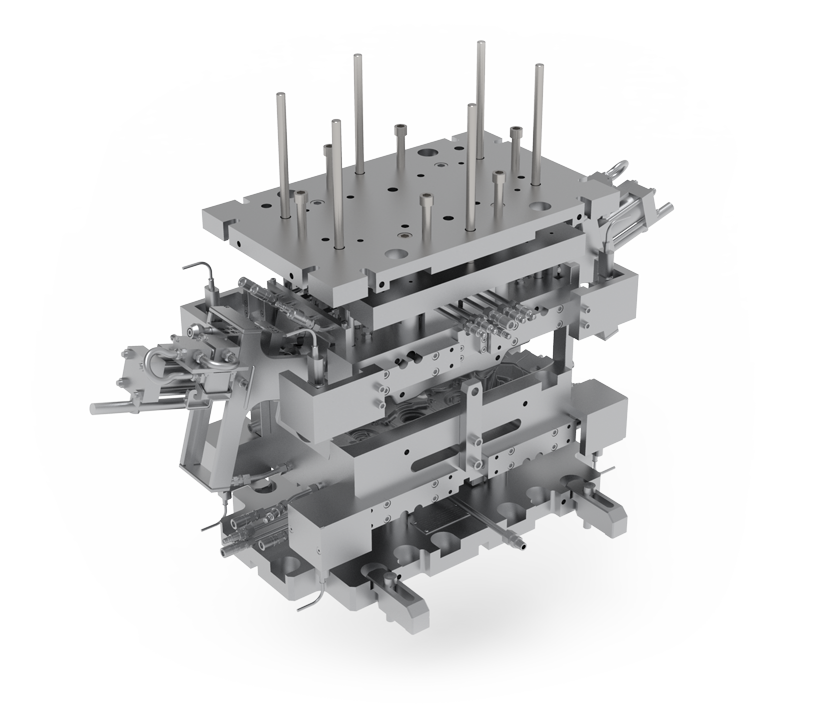

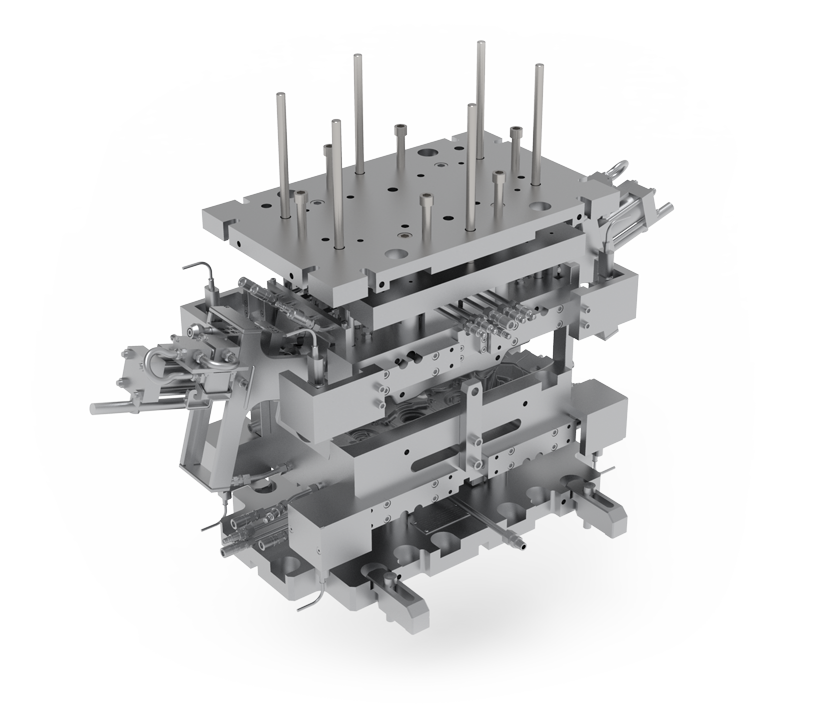

All our tools are designed in-house for greater flexibility and responsiveness. The tooling department interacts with the Product and Simulation departments to obtain the best solution.

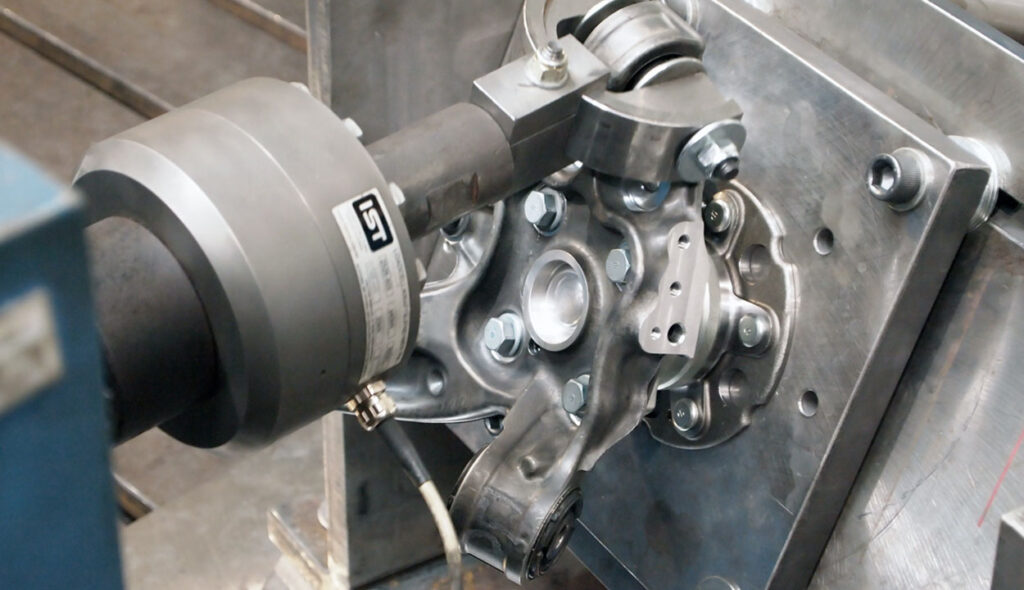

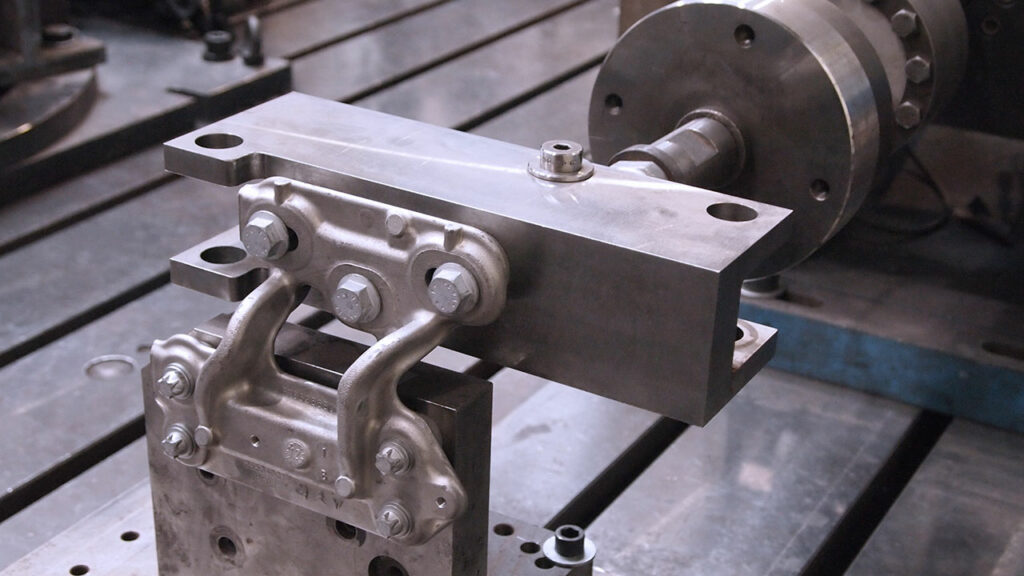

We have at our disposal multi-axis test benches to allow the final validation of the product before the industrialization for the series.

Some examples of tests that we carry out regularly :

All these tests are correlated to our numerical models, allowing us to enrich them if necessary to make them more accurate and reliable.