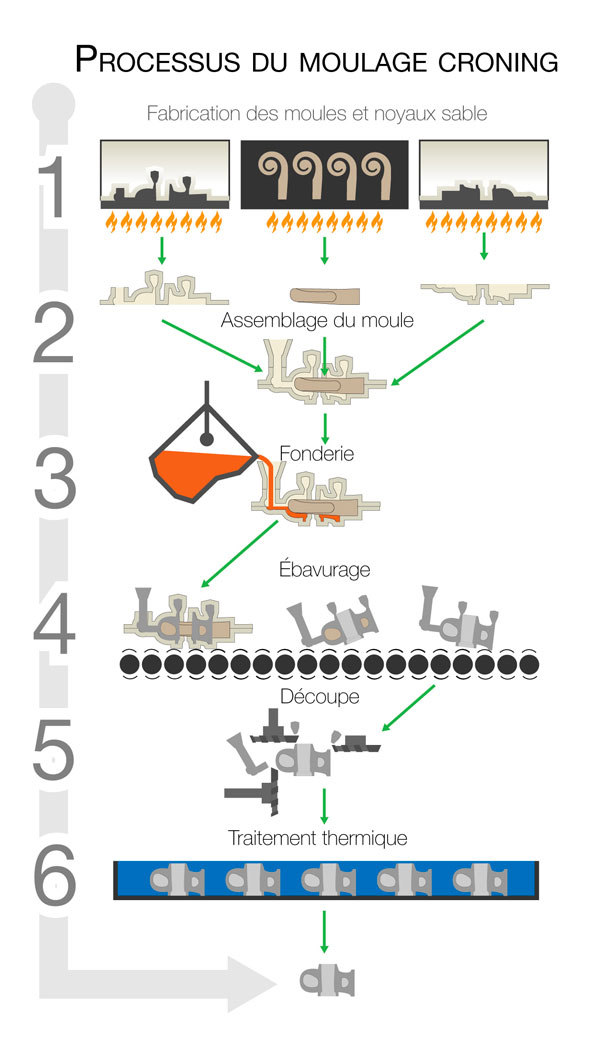

The shell moulding or “croning” process involves placing a sand mixed with a thermoplastic resin and a catalyst. The mixture is then brought into contact with tooling heated to between 200 and 300°C, creating a mould in the shape of the part. The molten steel is then poured inside to produce the final part. This process is used by Saint Jean Industries Laval to produce cast iron and steel parts. It produces an excellent surface finish and precision that is incomparable to other processes using sand.

Retarders, exhaust systems, turbochargers…